The team behind Celtic Marches, the independent Herefordshire cider makers, is embarking on a new venture with the launch of Marches Bottling and Packaging Ltd, a brand new bottling and packaging facility.

Celtic Marches made drinks industry news last year when they brought out Status Quo Down Down Cider, in conjunction with rock legends Francis Rossi and Rick Parfitt.

Celtic Marches made drinks industry news last year when they brought out Status Quo Down Down Cider, in conjunction with rock legends Francis Rossi and Rick Parfitt.

The opening of Marches Bottling & Packaging adds another string to the business’s bow. Susan Vaughan, a Director of Celtic Marches and the new company, spoke to Wholesale Manager.

Wholesale Manager – Susan, how did Celtic Marches as it is now come into being?

After a career with a major cider manufacturer and a break to bring up my young family, I joined my brother Robert Hancocks on the family farm in Bishops Frome, Herefordshire, where our family has been growing fruit and hops for over 100 years. Celtic Marches grew out of that.

WM – So who does what in the business?

I look after the sales, marketing and brand development. Robert grows the apples and makes the cider. Darren Morris looks after the finances. Chris Palmes oversees operations, production, the laboratory and our quality assurance.

WM – How big is Celtic Marches in turnover terms?

Our turnover is up 50% on a year ago and we’re expecting that growth rate to continue. We have capacity to produce 3 million litres a year and have nearly 200 acres of cider apples.

WM – What different products do you make? What are your best selling products in retail?

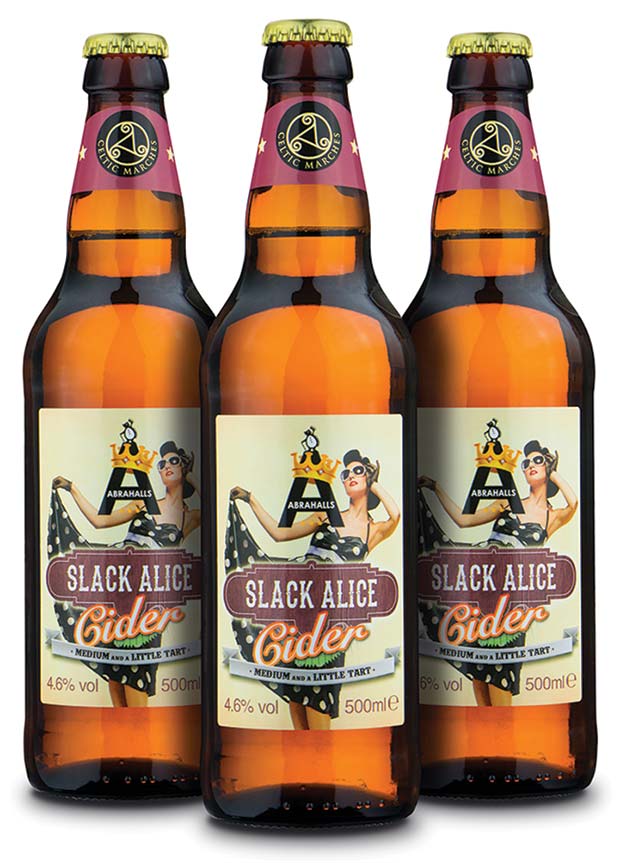

Our three core products are Thundering Molly (5.2% ABV), Slack Alice (4.6%) and Lily the Pink (4.5%), all Protected Geographic Indicator (PGI), made with Herefordshire cider apples and grown on the farm, which entitles us to put Herefordshire on the labels.

Our products are evenly distributed in the on trade and off trade and we export to 17 countries.

WM – And now you’re opening Marches Bottling and Packaging Ltd, a brand new bottling and packaging facility. Where is it based? How did it come about?

The new factory is on the outskirts of Bromyard in Herefordshire. We decided to open it because we were experiencing difficulty in having our products packaged and were getting frustrated. So we made a vertical move and opened our own packaging plant, which we plan to run as a separate company, handling our own products and offering contract packing to cider makers and brewers initially.

WM – Who are you targeting as your customers?

WM – Who are you targeting as your customers?

We’re targeting people like ourselves and small to medium sized cider makers without their own packaging facilities and small to medium sized brewers wanting contract packing.

Eventually we will offer the service to soft drinks and fruit juice companies as well. We are also offering recipe creation services in our laboratory as well as testing facilities.

WM – What bottling capacity has the new factory got? When do you see it being busy?

It’s a fully automated packaging facility, which can run three shifts if required. A lot of cider makers are packaging cider in spring, so from March to September will be a busy time.

WM – How are you recruiting customers?

We’re talking to our contacts in other businesses making cider and beer. We also have the potential to help wine and soft drinks businesses. We want people across the industry to come and talk to us; we see it as a very fluid business.

WM – What technical standards do you work to?

We have a fully equipped lab, which Campden Food & Drink Research Association is due to audit shortly and we are also applying for BRC and Soil Association accreditation.

WM – Will this be run as a separate business from Celtic Marches? Who is heading it up?

Yes, it’s a completely separate operation but the same four people will be the principals as per Celtic Marches.

WM – Who have you approached so far to be your first customers?

We’re talking to many smaller to medium cider manufacturers, both local to us and further afield. We’ve all worked with the major manufacturers and people recognise us as having the necessary expertise and experience.

WM – Where do you see Celtic Marches going from here?

WM – Where do you see Celtic Marches going from here?

Celtic Marches will continue to make their existing products and bring out new ones. Our target is to use our whole apple crop, which as I mentioned is nearly 200 acres of cider apples.

WM – What impact will you setting up Marches Bottling have on Celtic Marches as a company?

Marches Bottling will enable Celtic Marches to be more flexible and efficient because we won’t have such long lead times for production and cashflow will improve so we’ll be able to produce more “just in time.” Similarly it’s good news for other manufacturers, because if you have cider in tanks and can’t get it packed, you lose sales.

WM – Finally, speaking personally, what does it mean for you and the rest of the team?

It’ll be great to work closely with other smaller producers. We’re supporting our friends in the industry and giving them a boost. We’re not ready to go in for lifetime achievement awards yet, but it’s quite a milestone to be doing this! It’s an exciting project all round.

CELTIC MARCHES

Tel: 01684 569142

Email: sales@celticmarches.com

Marches Bottling & Packaging Ltd

Tel: 01885 489812

Email: Sales@marchesbp.com

Comments are closed.