A new year brings a chance to do things differently and is the ideal time to take stock of your performance and set plans in motion for your vision for the year ahead. Here are some areas for consideration, and some questions you could ask yourself.

Have you optimised your warehouse layout?

Have you optimised your warehouse layout?

Using a 3D simulation of your warehouse can demonstrate a flow of operations and identify where congestion or risks occur. It allows you to trial possible alternative layouts without commitment and is an excellent tool for demonstrating rationale for change and improvement.

Is your materials handling fleet working as hard for you as it could be?

Consider what equipment you are using, for what and when. It might be that you have a number of different units that you use for very specific jobs at different times. Are you able to replace any of those with one unit that has multiple uses? This could prove more cost effective than having spare units including the cost of the lease, the cost of maintenance and saves precious space.

How visible is your fleet performance to you?

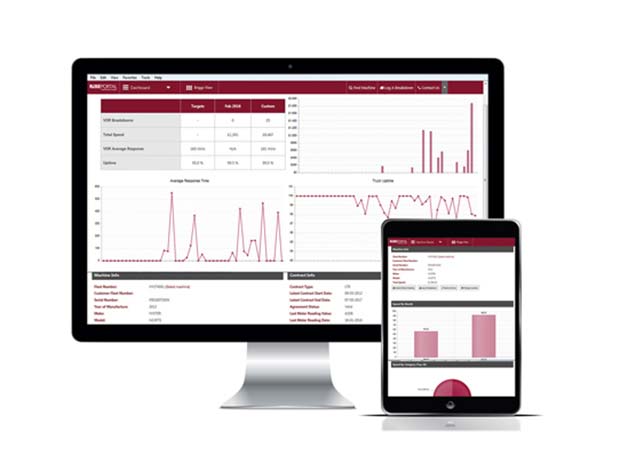

Did you know it is possible to track every aspect of your fleet’s performance from number of operational hours, to uptime, cost of repairs and servicing with figures from the entire fleet across multiple sites, by site and right down to each unique unit? This information is quickly accessible from an online reporting system and enables you to identify trends and reduce unnecessary costs.

Are there opportunities for safety gains?

Are there opportunities for safety gains?

As businesses grow, operations adapt and new staff members join the team, it is advisable to reassess the safety of your environment. This is particularly important if you have operators carrying out manual handling at height, or if there is high pedestrian traffic in close proximity to handling equipment.

If your team is handling stock at height, are they able to access it with complete safety? You can reduce the risk of falls by introducing Mobile Elevated Work Platforms which provide a solid grounding for staff to stand on and are enclosed so that the operator can’t fall.

Another example of a high risk situation is where there is high pedestrian traffic in a high noise environment. This can cause accidents at blind intersections as if pedestrians are not able to see or hear that equipment is exiting an aisle they may walk out in front of it. This risk can be reduced by adding Pedestrian Awareness Lighting (PAL) along with ‘red danger zone’ lighting to your equipment. The PAL provides advance warning of an approaching vehicle to pedestrians as a bright coloured light is projected onto the floor in front of, or behind, the moving vehicle. The red danger zone lighting works as a reminder to pedestrians to keep clear of a moving vehicle, ensuring they keep a safe distance from the forklift.

An additional safety consideration is the tidiness and cleanliness of your working environment. It is common sense that keeping a tidy work environment reduces safety hazards, but leaving debris over the warehouse floor can cause unnecessary damage to the equipment that drives over it. Ensure your cleaning equipment is fit for purpose and with a comprehensive range available that is suitable for every application there is no reason you can’t achieve the ideal safe environment.

As your trusted MHE advisor, Briggs Equipment can help you address all of these aspects and help you get ahead in the New Year.

Briggs Equipment is an engineering services and asset management specialist that has transformed the contract hire of industrial machinery.

BRIGGS EQUIPMENT

Comments are closed.